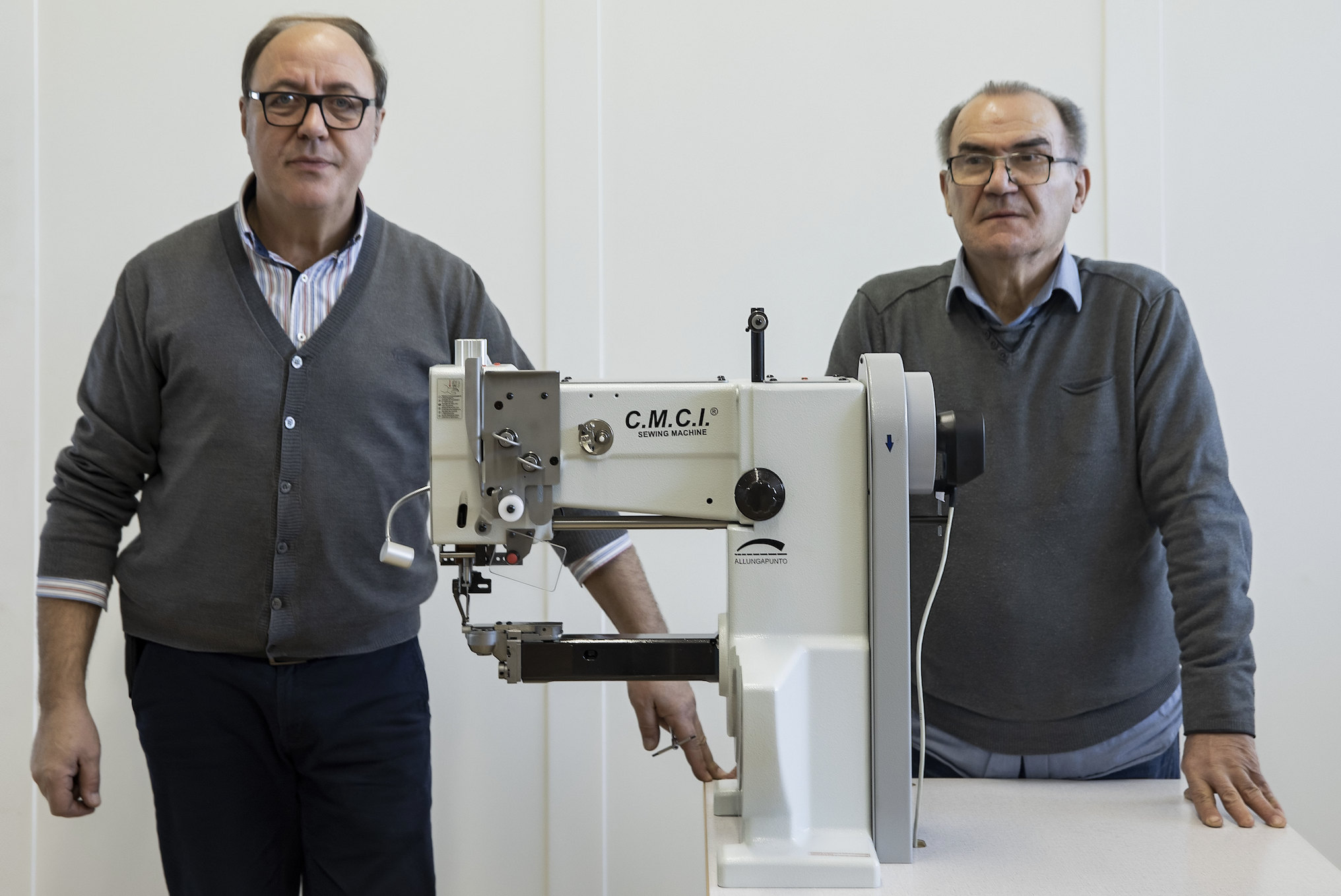

CMCI s.r.l. sewing machines to facilitate quality construction of shoes and bags

- Arsutoria Studio

- News

- 0 likes

- 28482 views

- 0 comments

Founded in 1974 under the name 'La Mocassino', CMCI s.r.l. produces industrial sewing machines for the footwear and leather goods sectors at an international level. If you are looking for one of the most advanced companies in the production of high-precision sewing machines, you have to go to the Marche region, where the majority of Italian shoe factories are concentrated and are pushing towards technological innovation and are among the most demanding customers in the sector. Once there, ask for CMCI s.r.l. A company that has demonstrated an unwavering commitment to research and development aimed at making the work of shoe and leather goods manufacturers increasingly easier and in line with the indispensable technological development that today's market demands. CMCI has a range of 18 different models of machines (each designed, researched, developed, built and tested for specific types of stitching). Not to mention the subclasses, all those optional accessories that increase the performance of each model. The marked flexibility demonstrated over all these years makes CMCI always ready to accept any new challenge that may be thrown at it in terms of new types of stitching, designs, yarns, etc. "If until a few years ago the greatest demands concerned patternmaking characterized by the Guardalo, today the technologies most in vogue are those dedicated to stitching Sneakers," they say from the company. Yet one of the most interesting machines in the Marche company's catalog is the MB74/2-B model for the production of Tubular/Mounted Moccasins. This is a machine that features two 70° inclined needles with oscillating looper, as well as a triple foot and needle-point transport. There is no lack of manual pincer ruffling, preset and variable by toggle during stitching. These are the seams it can perform: tubular and fitted moccasin welt stitching; tubular and fitted 45° stitching; tubular and fitted overlapping moccasin one-needle stitching; and tubular and fitted overlapping moccasin one-needle stitching for inverted moccasin. What can we expect in the coming months from CMCI? "As a company, we are always looking for new technologies capable of improving various processes, both in footwear and leather goods. We are currently working on the Strobel machine, to make it more robust and able to handle stitching even on safety shoes and the like. We are also designing a new model, which we will present at the SIMAC Fair in Milan 2024, that will work on different types of moccasins."

comments (0)