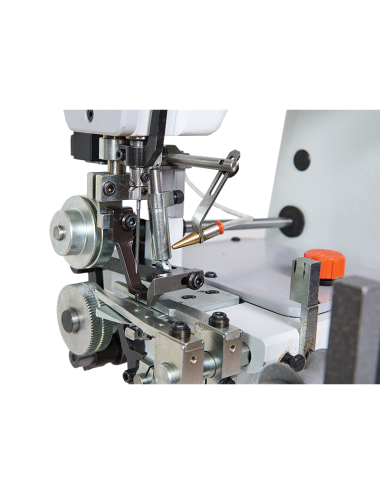

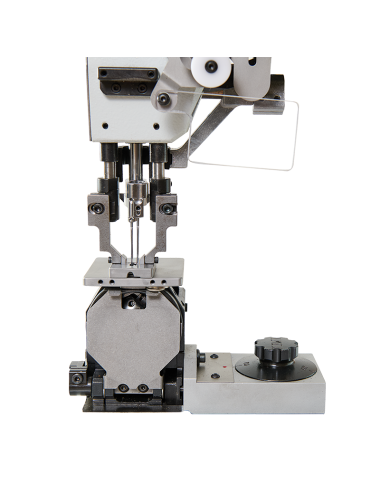

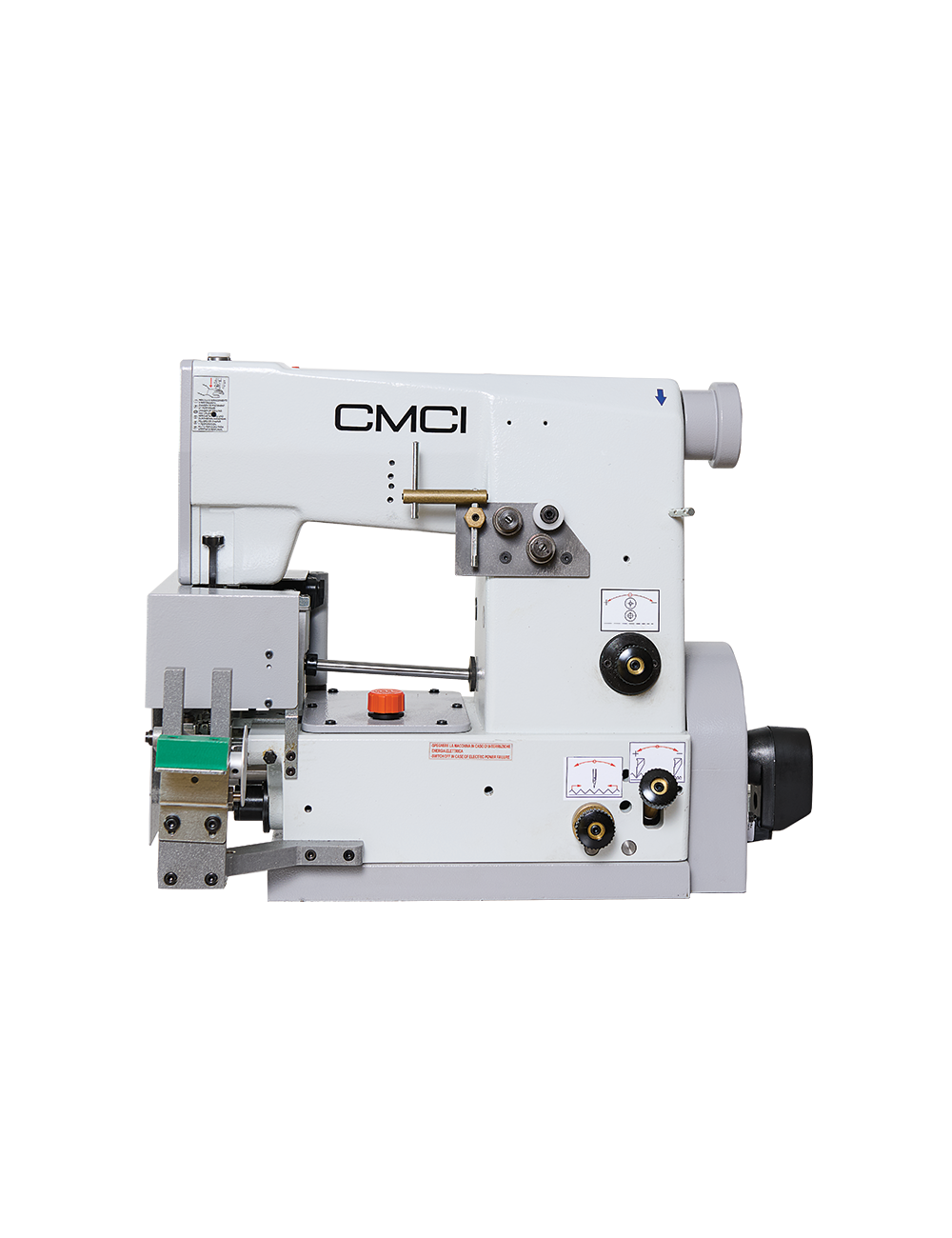

Technical features

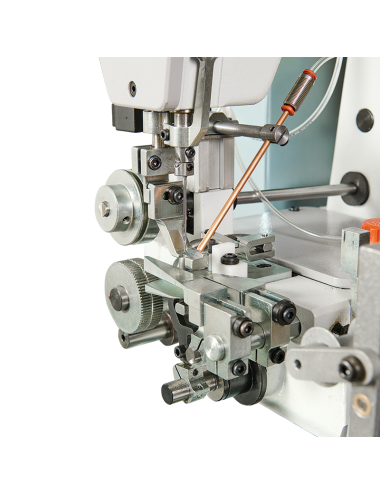

- Speed: 1100 stitches/min

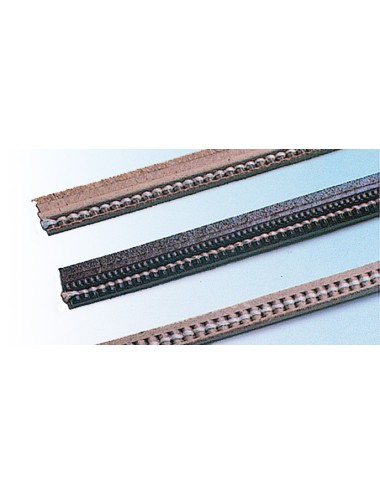

- Stitch length: 2-12 mm

- Threads: 0.6 - 1.4 mm

- Needle system: 328 - 214 x 1

- Motor: EFKA DC 1550 Control 220V 50/60 Hz

- Max. power consumption: 750 Kw

- Net weight: 147 kg

- Gross weight: 181 kg

- Packaging size carton on pallet: 124x70x150 cm

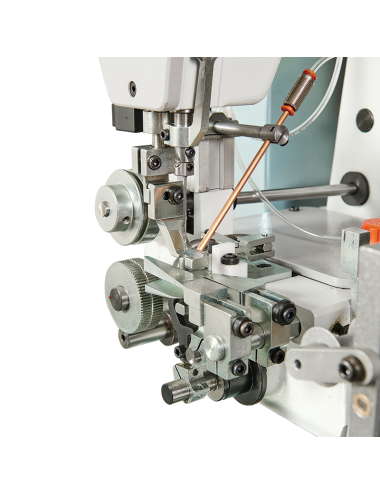

Product Details

Data sheet

- Functions

- Max sewing speed

- 1.100 punti/min

- Max stitch lenght

- 2-12 mm

- Needle system

- 328 - 214 x 1

- Voltage

- 220V 50/60 Hz

- Weight

- 147 kg

Quick Compare

Product |

G89

G89

|

G95 CG

G95 CG

|

G95 CG AR

G95 CG AR

|

F04 CG-VD

F04 CG-VD

|

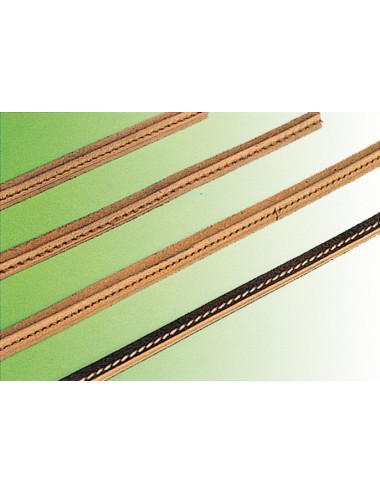

Description |

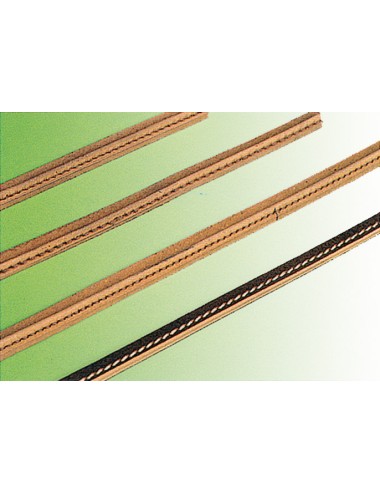

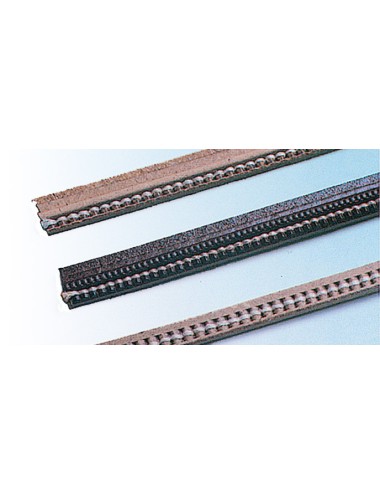

Flat welt sewing machine (saddle and leather)

|

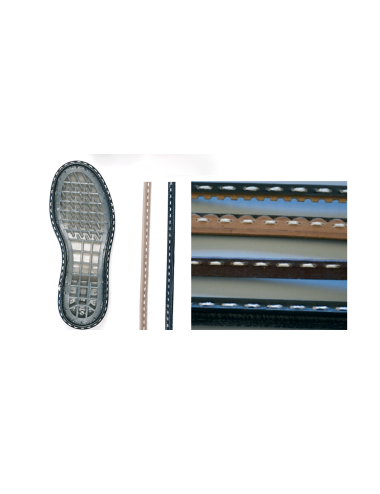

Flat machine for welt sewing (tr, pvc, calpa and leather)

|

Flat welt 1 needle sewing machine - two-thread chain stitch - (TR, PVC, rubber, salpa and leather): AR:

CG:

|

Flat welt sewing machine (TR, PVC, tack and leather)

|

Functions |

||||

Max sewing speed |

500 punti/min | 950 punti/min | 950 punti/min | 500 punti/min |

Max stitch lenght |

0-10 mm | 2-12 mm | 2-12 mm | 0-10 mm |

Needle system |

4011 o 4035 | |||

Voltage |

220V 50/60 Hz | 220V 50/60 Hz | 220V 50/60 Hz | 220V 50/60 Hz |

Weight |

125 kg | 160 kg | 162 kg | 125 kg |